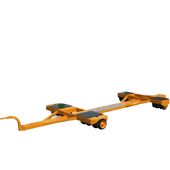

Trailer trolleys

Trailer trolleys based on 100 years of techniques and skills

Improve the efficiency of your company with Officine Bertoli trailer trolley

Each trailer trolley is designed to allow for safe and efficient work management.

We offer our know-how and experience to develop solutions. Dimensions, capacity, and equipment are diversified in relation to the customer’s needs in terms of flexibility and objectives. This customization is important because every detail is adapted to the specific needs of the customer, which helps in “paving the way for the efficient streamlining of workflows”.

Safety as the focus of our trailer trolley

The trailer trolley we produce for our customers aim to optimize daily activities, leading to an improvement in terms of safety.

They are equipped with a parking brake and they can be equipped with a service brake, to increase safety standards.

The trailer carts have the possibility of being linked together to form a convoy which is suitable for mechanized towing using an industrial tractor. To achieve this, the cart is fitted with both a front tow bar and a rear tow hook.

Every detail of the trolley contributes to optimizing the movement of goods and stuff, adapting to the available workspace.

Goals and benefits of lean production

“Lean production” (or “line feeding”) is a working method for manufacturing companies that aims to minimize downtime and low-value activities, maximizing the efficiency of the production area.

They make transporting and retrieving raw materials and equipment significantly easier, guaranteeing that your production line staff always have everything necessary right at their disposal for efficient production and machinery maintenance.

Why choose Officine Bertoli trailer trolley?

- Significant saving of time and resources and the general optimization of daily activities.

- The functionality of the trolleys due to the great possibility of customization.

- The possibility of setting up the trailers with optional accessories.

- The wheels are made of vulcanized rubber: they are non-marking, oil-resistant, and solvent-resistant, maintain optimal functionality at temperatures from +180°C to – 45°C and guarantee greater smoothness/slideability.

Over the years we have worked with Toyota, Still, Toyota, Jungheinrich and many others.